Media / Inside View

Skydrive

Media / Inside View — Skydrive

Making travel safer,

on the road and in the sky.

The future has already begun

A world filled with electric vertical takeoff and landing (eVTOL) and flying vehicles may still seem like science fiction to many people, however, much of this technology already exists and many companies are preparing to bring these new forms of transportation to market in the next few years. One of the front-runners is a “flying car” borne from a partnership between CARTIVATOR and SkyDrive, and their goal is to commercialize it by 2023.

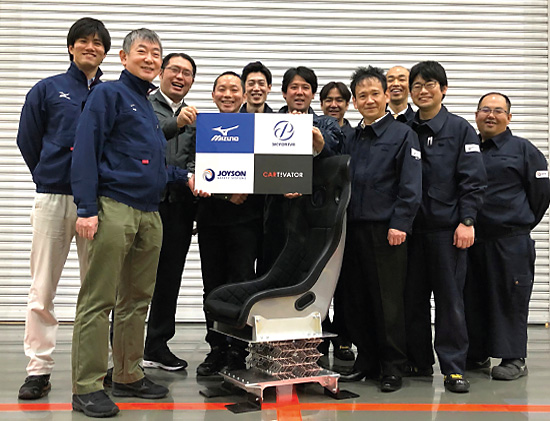

One crucial piece for this new flying car venture is occupant safety, which includes developing an aircraft body and architecture that will protect passengers in emergency landings and other situations. To do this, CARTIVATOR and Skydive recently revealed their work with Japanese sporting goods maker MIZUNO to design a lightweight, high performance energy absorption seating system, and Joyson Safety Systems to utilize our testing capabilities and lifesaving know-how.

Even the future needs safety systems

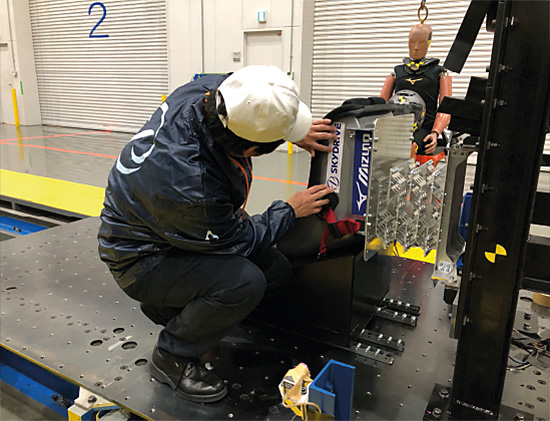

The task for JSS was to devise a testing method that could verify energy absorption characteristics and test the use of sheet and energy absorbing material when the flying car is dropped from a defined height. Since many specifications and verification data of safety devices like airbags and seatbelts still need to be defined and regulated for cars that fly, it was uniquely challenging to define a test methodology that could replicate these specific situations. To answer this need JSS developed a SLED test to simulate a collision state to measure performance of prototype passenger seats and safety devices.

The safety performance

In early March, the teams from CARTIVATOR, SkyDrive, MIZUNO and JSS gathered at our facility in Echigawa, Japan to observe the safety performance of the MIZUNO Wave seat prototype. The results were very promising. The MIZUNO Wave performed as designed and proved that it is possible to reduce the suppression load on an occupant’s lumbar spine to a much lower level than in general aircraft seats.

The next milestone in this exciting project will be to conduct Sled testing to measure performance of the seating system during a 10-meter fall. Joyson aims to perform these tests in June and July and looks forward to sharing positive results.

Joyson Safety Systems 2020